REPORT

EXAMPLE

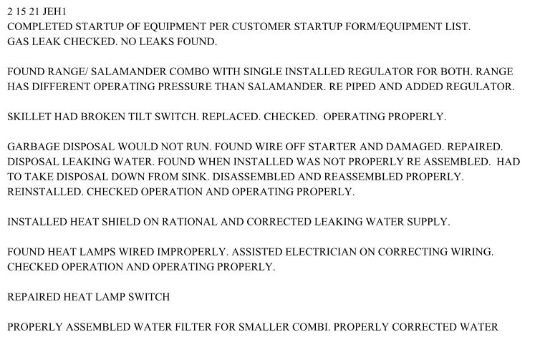

Example of recent report and corrections made

A. Cleaning and Protection:

B. Final Observation: Provided by Food Service Design Consultant when the General Contractor will certify that the work is complete, has made a thorough review of the installation and operation of each item in the contract and found it to be in compliance with the Construction Documents.

C. Repetitive Final Observations: In excess of two, and all costs associated thereto which may be incurred due to the General Contractor's failure to comply with the requirements of this article will be invoiced on a time and expense basis and reimbursed to Food Service Design Consultant.

D. Contractor's List of Incomplete Items: The FSEC will complete a walkthrough with GC and architect and issue detailed punch list report for actions needed to be taken.

- Procedures will be in compliance with Section 01 7700 "Closeout Procedures."

- GC to consolidate all punch list inspections reports (Food Service, Architects, Engineers and GC) to one report.

E. Installation, Connections, and Testing: To be complete a minimum of five (5) days prior to Owner takeover.

12. Performance Check - Verification, by an authorized service technician, that the manufacturer’s installation specifications are met, and utilities are correct for newly installed equipment. To ensure proper operation of the piece of equipment, an authorized technician, may need to perform minor adjustments, alignments and calibrations. Performance checks are done any time after equipment has been in operation for a minimum of two weeks to a maximum of 90 days.a. Provide CFESA Recommended Start-Up/Performance Check Form - Form shall be completed by the authorized service technician with copies provided to the FSEC The FSEC will be responsible for forwarding completed copies to SHG(who will provide the final bond copy of all completed forms to the Owner/End User when all work is finalized) and the manufacturer representative (who will provide a copy to the manufacturer if required). See exhibit 3 for the required form. Original form files are available upon request from SCOPOS Hospitality Group, CFESA and MAFSI for reproduction as required.

a. CFESA Recommended Start-Up/Performance Check Form - Form shall be completed by the authorized service technician. with copies provided to the FSEC. The FFSEC will be responsible for forwarding completed copies to SHG (who will provide the final bond copy of all completed forms to the Owner/End User when all work is finalized) and the manufacturer representative (who will provide a copy to the manufacturer if required). See exhibit 3 for the required form. Original form files are available upon request from SCOPOS Hospitality Group, CFESA and MAFSI for reproduction as required.

G. Certification Letters and Portal Monitoring Accounts:

- FSEC to provide all of the following certification letters and account access information as applicable for the project

- Letters of certification for dishwasher operation and sanitation compliance

- Letter of certification for the Accurex Hood.

- Letter of Certification and SDV - System Design Verification from Captive-air Hoods indicating proper EMS and VFD operation.

- Provide log-in access for Captive-Aire hood operation and maintenance monitoring. Set-up with owner and program automatic error notifications to be notified via email or text as preferred by facilities.

- Provide log-in access for temperature monitoring portal to motor all refrigeration unit as specified with Victory’s SecureTemp system. A live report should be provided showing all units configured and labeled in system using designed item number and short description of unit type and location. Set-up with owner and program automatic notifications to be notified via email or text as preferred by facilities.

H. Demonstration and Training: Provide demonstrations for use of all equipment, item by item, including fabricated equipment as requested by Owner or Dining Services.

- Demonstrations to be conducted by factory trained individuals, typically a factory representative firm.

- Instruction shall include care and cleaning of all equipment and a complete demonstration of operation

- All buy-out equipment shall be demonstrated by factory trained personnel only.

- All actions within the demonstration should be referenced in the operator manual as prepared by the manufacturer of said piece of equipment.

2. General Contractor will provide a letter, signed by all sub-contractors involved and co-signed by the Owner's Representative stating that dining staff have been adequately instructed in the use of equipment.

3. MAFSI Recommended Demonstration Request Form - Form shall be completed by the FSEC with copies provided to the manufacturer representative. The manufacturer representative will be responsible for forwarding completed copies to SHG (who will provide the final bond copy of all completed forms to the Owner/End User when all work is finalized). The manufacturer representative is responsible for forwarding a copy to the manufacturer if required. See exhibit 4 for the required form. Original form files are available upon request from SCOPOS Hospitality Group, CFESA and MAFSI for reproduction as required.

4. MAFSI Recommended Demonstration Inspection Report - Form shall be completed by the manufacturer representative with completed copies provided to the F.E.C. The FSEC will be responsible for forwarding copies to SHG (who will provide the final bond copy of all completed forms to the Owner/End User when all work is finalized). The manufacturer representative is responsible for forwarding a copy to the manufacturer if required. See exhibit 5 for the required form. Original form files are available upon request from SCOPOS Hospitality Group, CFESA and MAFSI for reproduction as required.

I. In addition to the guarantee called for under the General Conditions, this FSEC shall further agree that in the event of failure of any system or item of equipment or improper functioning of specified work during the guarantee period, he shall have "on call" competent service personal available to make the necessary repairs or replacements of specified work promptly at no cost to the Owner. In the event that replacement of an entire item is required, the Owner shall have the option of full use of the defective equipment until a replacement has been delivered and completely installed.