5.6 Food Service Equipment Contractor Responsibilities

- A. General: Cooperate fully with the General Contractor so work may be carried out smoothly, without interfering with or delaying other work for this Contract or work by Owner. Dealer is responsible for reviewing, correcting, and guiding food service fabrication process, installation requirements, and codes. Dealer to follow formal protocol and flag any code or compliance issues, submitting RFI’s or noting issues on submittals.

- Coordination of Information: FSEC will coordinate information required by other trades relating to food service equipment and hold a meeting with GC discussing requirements specific for this project. Dealer to provide and generate a “Discipline Coordination Sheet” clearly defining scope of work performed by dealer and scope of work expected by other trades. See attached “Exhibit B - Discipline Coordination Sheet” at the end of this specification.

- Subcontracting of Work: Is allowed where due to jurisdictional agreements and/or conditions must be done by others. This is at the expense of the FSEC. Some subcontractors may include Millwork, Stainless Steel Fabrication, Fire Suppression, Refrigeration, etc.

- Coordinate details and scheduling work at site with other work to avoid unnecessary interference or damage. Dealer to submit a “Project Plan” outlining sequence of delivery items, like, hoods, walk-in boxes, equipment, millwork, etc. See attached “Exhibit C - Project Plan” at the end of this specification.

- Installer's Qualifications: Work will be completed by experienced installers in accordance with Drawings and Specifications.

- Staffing Level: Employ qualified installers and supervisors to complete the work without delay.

- Final Connections: Notify in writing, a minimum of five (5) days in advance, all trades involved in final connections of food service equipment and prior to beginning of this installation.

- Installation and Supervision: Continuous during normal job hours until all equipment is installed and connected.

1. EXISTING EQUIPMENT (FOOD SERVICE EQUIPMENT CONTRACTOR):

- The term "existing equipment" as used in this specification shall mean food service equipment now in storage or active use by the Owner. Where such equipment is reused it shall be the responsibility of the Food Service Equipment Contractor (section 11 40 00) to carefully examine each unit beforehand to ascertain proper fitting and alignment in its new location.

- The Food Service Equipment Contractor (section 11 40 00) shall verify and indicate on his rough in plan all utility connections required for the proper installation of existing equipment to be reused.

- GC is responsible for the removal, cleaning, storage, and relocation of the equipment. GC shall coordinate to disconnect and reconnect of services, if required, shall be performed by related trades; final required utility connections to be verified by Plumber/Electrician. All Final connections by Electrician/Plumber.

- FSEC to inspect existing equipment and present a separate proposal fee if any repair/replacement of parts as necessary for item to operate in accordance with manufacturer requirements and specifications.

- A thorough scraping and steam cleaning to remove scale and all foreign material;

- Repainting of all items having exposed, worn, or scarred surfaces which are not of rustproof materials;

- Furnishing any required filler pieces, braces, hardware, and so on necessary to complete the installation in a workmanlike manner.

- Repainting of the understructure (legs, shelves, drawers, etc.) where required shall be in aluminum lacquer or other chip resistant finish. Other items shall be completely repainted or touched up, as required by their condition, in their original color.

- Refrigeration equipment shall have all components checked for efficient operation, and all worn or malfunctioning items shall be replaced.

- Items containing heating elements shall be checked and any electrical components not functioning properly shall be replaced.

4. The GC is responsible for removing and disposing of existing food service equipment which is not to be reused and shall verify with the Owner and obtain written release prior to removing such equipment. The GC shall retain any salvage value, unless specified otherwise by the owner.

5. A schedule of relocating existing equipment shall be determined before the Contract is awarded. If changes are made that cause additional charges, the company causing such changes will be responsible for the costs involved.

- Equipment Digital base plan may be requested from Consultant and will be provided by FSEC use in preparation of submittals. Electric/Plumbing rough-ins, equipment details, and millwork sections will not be provided as these need to be generated by the FSEC completing final step of due diligence check generating technical submittals illustrating what is being supplied, how it will be fabricated and how it will be installed. Copying and pasting design document details will not be permitted. All shop drawings are to be submitted to scale or they will be rejected. Hand drawn shop drawings will be rejected.

- Obtain copies of the latest architectural plans from architect prior to beginning the dimensioned rough-in submittal plans. Submittals are to be based off latest set of drawings, including all addendum/revision released.

- Submittals are to be coordinated between all engineered systems by FSEC before submitting for review. FSEC is to take ownership of all submittals.

- Review all shop drawings internally prior to submitting to SHG, especially those that are typically auto generated and are not accurate. check for accessories, utility ratings and dimensions. SHG will reject submittals if they are found to be completely off and not line up with project.

- Submittals to be sent as a complete package; partial or incomplete submittals will be rejected by GC/Architect/Consultant. Equipment Plans should not be submitted without equipment cutbooks or vice versa. Both need to be submitted together for comprehensive submittal review.

- Submittals are to be separated out, per specifications. Not lumped together as (1) large submittal file

- All Equipment plans and rough-in drawings to utilize FS design corresponding item numbers. Do not create your own numbering system.

- Shop Drawings should not read "confirm" or "verify" - you the dealer as part of the submittal process needs to close those gasp via formal RFI's if need or site survey dimensions or dictate a hold dimension on shop drawings if need be.

- Shop drawings to include all equipment, including by others for proper spacing verification. Especially millwork shop drawings. Do not submit millwork only with gaps. Exact actual equipment to be shown and how the millwork is constructed around it for proper fabrication, reinforcement and clearances.

- Equipment Floor Plans and Dimensioned Rough ins for Electric and Plumbing & any chase drawings (soda runs, refrigerant runs, beer lines, etc). See section 11 below for further requirements on this submittal.

- Custom Fabricated Shop Drawings, Exhaust Hood, Stainless Steel Fabrication, Millwork etc. See section 10 bellow for further requirements on this submittal.

- Sneezeguard submittals to be reviewed and coordinated with Millwork, uncoordinated default system generated guards will be rejected. Sneezeguard submittal to be reviewed by millwork fabricator and signed off

- Equipment Cut-Book complete with numbered cover sheets and accessory listing. See section 12 bellow for further requirements on this submittal.

- "General Responsibility Outline" sheet defining roles and responsibility for all relevant project scope. Refer to SHG Exhibit 6 Form, feel free to replicate and update as relevant.

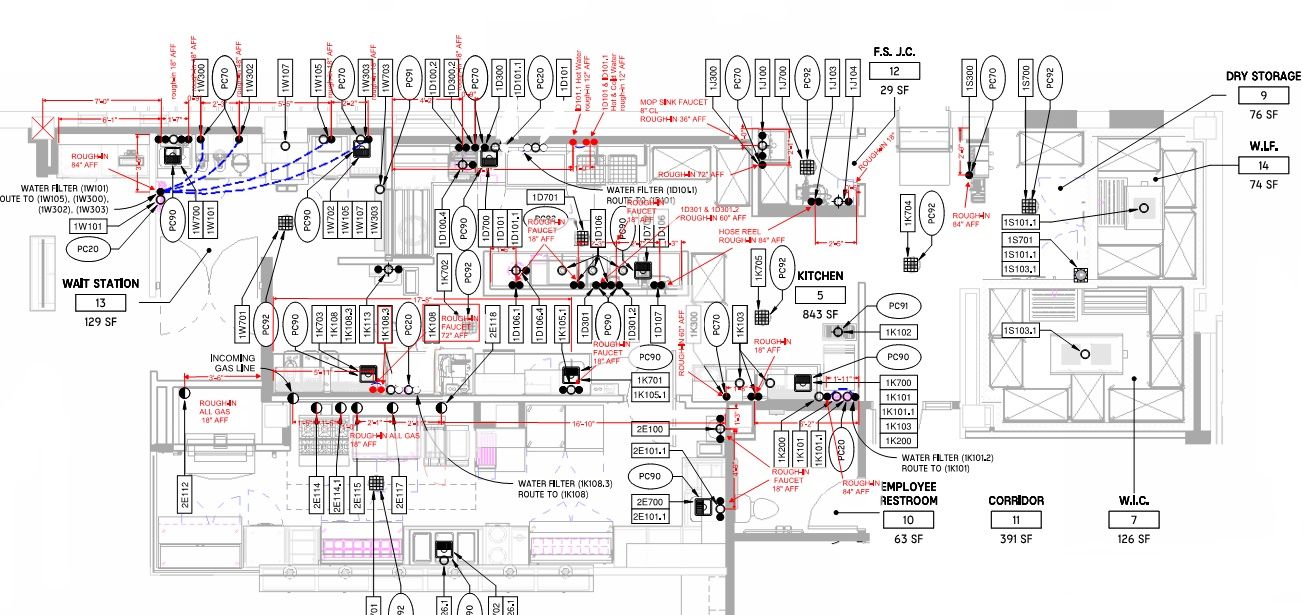

11. Equipment Floor Plans and Dimensioned Rough ins for Electric and Plumbing.

a. Within 30 working days from award of contract, the Food Service Equipment Contractor (section 11 40 00) shall submit electronic PDF files of the following drawings to the Owner or his designated representative for review:

b. The scale of these drawings shall be 1/4" = 1' 0", and it shall be the responsibility of the Food Service Equipment Contractor (section 11 40 00) to ensure that his drawings are properly coordinated and that there are no conflicts between sheets. The Food Service Equipment Contractor (section 11 40 00) may, at his option, combine [(b) and (c)] and [(d) and (e)], providing that the scale of all drawings is increased to 1/2" = 1' 0".

- A floor plan of all food service areas showing all items of equipment and sufficient dimensions to indicate placement of equipment from walls, other items, etc. This sheet shall include an equipment schedule indicating item number, quantity, and description. This sheet is to be based on the Architect's dimensional drawings or field review of existing conditions, whichever is available. Under no circumstances will a tracing from the Architect's or Consultant's work be acceptable.

- A completely and clearly dimensioned electrical rough in plan indicating exact locations, heights, and services required for each item of food service equipment, as well as any incidental services (for example, convenience receptacles) shown on the Consultant's spot connection plan. This sheet shall also include an equipment schedule, and each utility description on the body of the sheet shall be accompanied by the appropriate item number. It is expected that the Food Service Equipment Contractor (section 11 40 00) will refer to the data prepared by the Architect and Consultant to complete this requirement; however, it is the responsibility of the Food Service Equipment Contractor (section 11 40 00) to verify information shown thereon, and submittal by the Food Service Equipment Contractor (section 11 40 00) will warrant that he is fully satisfied that the information shown on the submittal is totally correct, complete, and ready for use in the field by other trades. On a new project, rough in dimensions shall be calculated from column center lines or other established datum points. On a project in an existing space, calculations shall be from finished walls. Indicate all interconnection requirements by other trades.

- A plumbing rough in plan conforming to the requirements noted in (b) above.

- A chase provision drawings indicating soda line PVC chases, Refrigerant Line PVC Chases and/or Beer Line PVC Chases. Plan is to show full detailed runs/rises from source to destination with all penetration detail, sweep curve, etc. GC - General Contract will utilize these to provide the PVC chase.

- A building conditions plan conforming to the requirements noted in (b) above, and including all pertinent information regarding masonry bases, curbs, recesses, critical dimensions of walls and openings, wall anchorages and overhead supports, and any other special information required to insure a properly completed installation.

c. The review of these drawings by the Owner or his designated representative is for design purposes only, and that review and/or the reviewer's election to review drawings submitted not in accordance with the above directions will not relieve the Food Service Equipment Contractor (section 11 40 00) from responsibility for the consequences of not having prepared the drawings as above described.

d. The Food Service Equipment Contractor (section 11 40 00) shall be fully responsible for the accuracy of all submissions and drawings made by him. If such mechanical, electrical, refrigeration, illumination, service lines or ventilation service lines are not properly installed because of errors or omissions on said drawings, it shall be the duty of the Food Service Equipment Contractor (section 11 40 00) to remove, relocate or install new lines at his own expense. Cutting, patching, installing, removing or relocating of such utilities shall be done as directed by the Architect and/or Consultant.

e. The Food Service Equipment Contractor (section 11 40 00) should attend a slab rough-in inspection before slab is poured to confirm locations of major stub-ups.

10. Manufacturer's Drawings:

11. Shop Fabrication Drawings:

- It is the responsibility of the Food Service Equipment Contractor (section 11 40 00) to ensure that drawings required from his vendors are received and submitted so as to allow review, correction, re-submittal, and production within the requirements of the project schedule.

- The Food Service Equipment Contractor (section 11 40 00) shall review, coordinate, and correct these drawings before submitting them for review. Submit electronic copies for review and approval.

- The Food Service Equipment Contractor (section 11 40 00) is responsible for verifying that notes and revisions on these drawings do not conflict with his rough in drawings and shall immediately notify the Owner or his representative of any such conflicts.

12. Manufacturers' Illustrations:

- Within 30 working days from award of contract the Food Service Equipment Contractor (section 11 40 00) shall submit electronic PDF files of the following drawings showing complete fabrication details of custom fabricated equipment.

- The scale of these drawings shall be 3/4" = 1' 0", with sufficient cross sections to accurately describe construction. Sections shall be at a scale of 1 1/2" = 1' 0". Each drawing shall show name and address of fabricator.

- These drawings shall indicate locations of utilities and interconnections in relation to the custom equipment. Junction boxes and breaker panels shall be presented in schedule form showing individual connections and total load. If requested by the Owner, provide complete wiring diagrams. The sepia copy will be returned.

- Shop drawings shall indicate all pertinent details, including item number, type of material, gauge of material, method of fastening, dimensions, hardware, model numbers, location and size of mechanical and electrical connections, number of units required. Where an item of standard production line equipment, i.e., "buy-out" item, is mounted on, or adjacent to a shop fabricated item, it shall be shown in outline form on plan and elevation, accurately scaled, to indicate relationship and clearances.

- All fabricators involved should be aware that the project has bought the details specified and the design team will be conducting site inspection and will require that everything gets replaced that does not conform to those details. This is related to Stainless Steel custom fabrication and Food service Millwork. Submittals should reflect all of the details and how they intend to be constructed. Submittals without those details will be rejected for resubmission.

- After final approval of shop drawings, the Food Service Equipment Contractor (section 11 40 00) shall furnish additional copies as requested.

- Approval of shop drawings shall not relieve the Food Service Equipment Contractor (section 11 40 00) from full compliance with the Contract drawings and specifications unless any deviation from same has been brought to the Consultant's attention in writing and approval for same has been given in writing.

- Within 30 working days from award of contract, the Food Service Equipment Contractor (section 11 40 00) shall submit electronic PDF files of the equipment cut book to the Owner or his designated representative for review:

- Provide a cover sheet for each item number, indicating item number, quantity, description, manufacturer, model number, utilities. required, and accessories

13. The review of these items by the Owner or his representative is for the assistance of the Food Service Equipment Contractor (section 11 40 00) and does not relieve the Food Service Equipment Contractor (section 11 40 00) of any responsibility for accuracy and completeness. When the Food Service Equipment Contractor (section 11 40 00) is notified that further resubmittals will not be required, he shall provide to the Owner a reasonable number of copies of prints and brochures without charge.

- The project specifications may contain pieces of equipment that are Energy Star Certified and may qualify for an instant rebate from the utility providing service to the installation address. The awarded Food Service Equipment Contractor of this bid is to engage the team from Energy Solutions who will determine the equipment eligibility/rebate amount and file for the qualifying rebates. Food Service Equipment Contractor will be required to provide a line-item discount to the customer and provide proof of discount on final billing. Please contact Ed Wiernasz at Energy Solutions for more information. ewiernasz@energy-solution.com office 510-482-4420 x461 cell 860-614-5051.

examples

Submittal examples

Not acceptable submittal